Integrating gasification with electrolytic hydrogen for SAF production

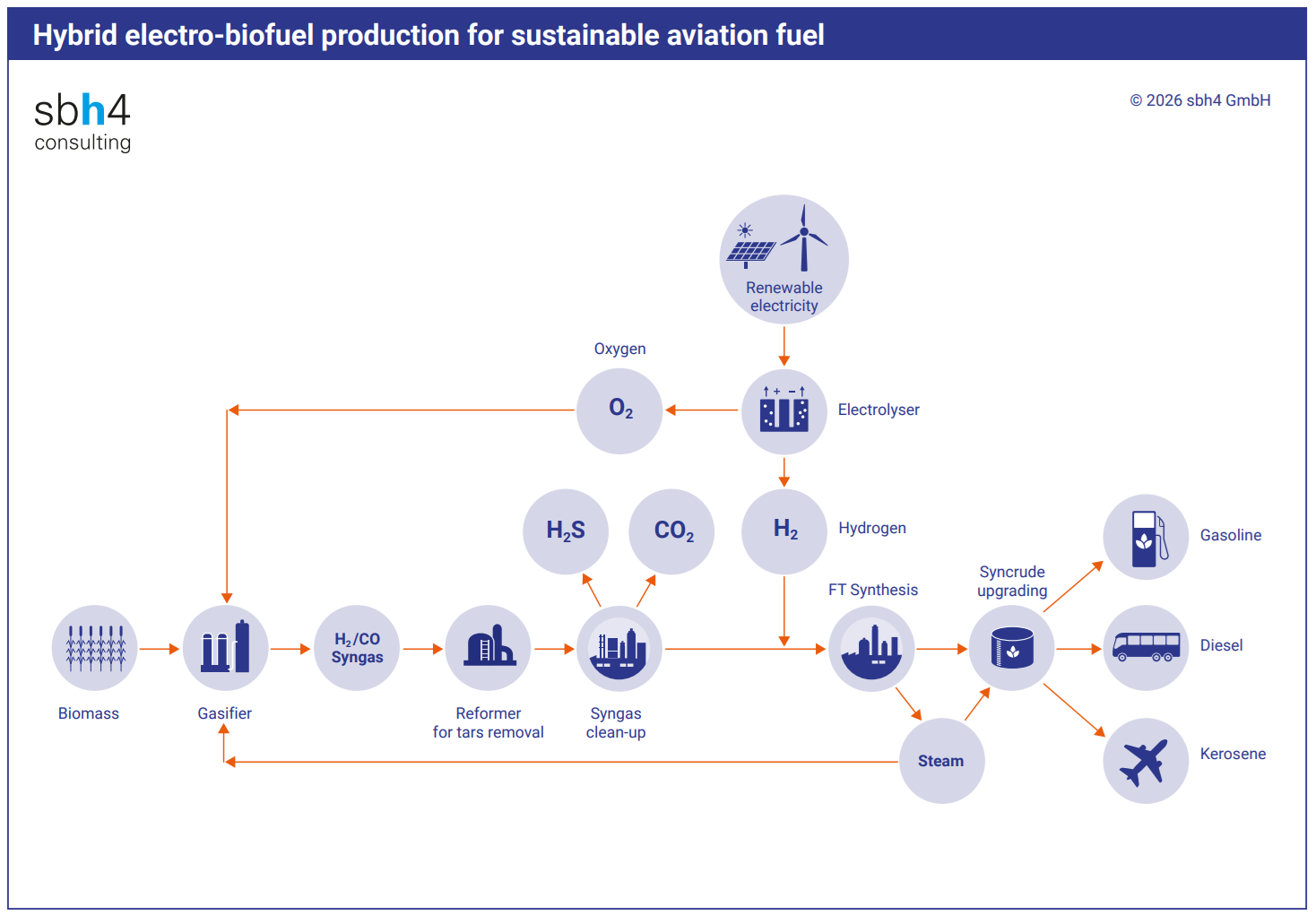

Hybrid bio-electrofuels combine electrolytic hydrogen with syngas from biomass gasification to achieve the perfect balance of hydrogen and carbon monoxide in syngas. The result is affordable and scalable sustainable methanol or aviation fuel (SAF) production.

Sustainable synergy

Gasification of residual biomass, such as forestry cuttings and post-harvest waste, is an alternative pathway to achieve liquid fuels. These are pre-consumer wastes. Gasification of wastes to produce methanol or SAF results in a lower cost fuel than the power to liquids (PtL) electrofuels route.

The challenge of this process is that the syngas produced by gasification is very rich in carbon monoxide (CO) but it does not contain sufficient hydrogen to produce liquid fuels such as methanol, kerosene and diesel.

Looking to the very long term, the amount of available forestry waste is finite and driven by timber production, which is the primary use of the harvested tree. However, at present much of this residual forestry waste is left to rot on the forest floor, resulting in undesirable methane emissions. So there is a long way to go before this feedstock is fully utilised.

PtL electrofuels derived from renewable electricity sources and electrolytic green hydrogen may be scalable in the future. However, at present a pertinent question about electrofuels is whether they are the best use of green electrons whilst there is such a surging demand for electricity around the world and the majority of power generation capacity still relies on fossil fuels.

The combination of these two processes can create a harmonious synergy. The forestry waste biomass can be stretched through the use of electrolytic hydrogen to mitigate any potential scalability concerns. And, carbon from the biomass is fully utilised with minimal carbon dioxide emissions.

Furthermore, the high cost of the PtL electrofuel is diluted by the combination with affordable waste biomass feedstock.

Gasification of post-consumer waste

To ease any potential scalability concerns related to biomass feedstock, municipal solid waste (MSW) can be used as an alternative to biomass in the gasifier. Industrial wastes, such as car seat foam and fabric waste can also be used. Post-consumer waste wood from building demolition or fitted kitchen replacements is also an ideal gasifier feedstock.

MSW contain about 50% of biogenic material. Furthermore, the re-use of the fossil components of MSW or industrial waste to produce fuel avoids the need to extract virgin fossil fuels and thereby reduces overall CO2 emissions. In both cases, the lifecycle analysis favours the use of these feedstocks over virgin petroleum.

Residual forestry biomass or waste wood may cost in the order of €100 per tonne when chipped and delivered to the gasifier. On the other hand, use of MSW or industrial waste will generally result in a ‘gate-fee’ revenue stream for waste disposal which may be in the order of €50 to €100 per tonne. This gate fee supplements the revenue stream and compliments the sale of fuels derived from the process. This additional revenue can improve the project economics and tip the balance in favour of using MSW or industrial waste as part of gasifier feedstock.

Industrial scale gasifiers - Image courtesy of Air Products and Chemicals, Inc

Carbon management and syngas clean-up

During gasification, the ideal chemistry would be that the hydrocarbon feedstock is converted only to hydrogen and carbon monoxide. However, the gasifier cannot be controlled to this level of precision. Some heavier molecules break through as tars and other molecules are combusted to produce CO2.

Use of oxygen instead of air, injection of steam with the oxygen and gasifier operation at high temperature around 1,400 °C, as is the case in a slagging entrained flow gasifier, can maximise the conversion of carbon to CO. Maximising CO production maximises the liquid fuels product yield from the biomass feedstock and simultaneously minimises CO2 emissions from the process.

After the gasifier, the syngas must be cleaned prior to methanol synthesis or other liquid fuels production in Fischer Tropsch Synthesis (FTS). If they are present, tars can be removed using a secondary reforming stage. This generates additional syngas.

CO2 and other acid gases such as hydrogen sulphide can be removed using a solvent-based scrubbing and stripping system. This type of equipment is commonly used in natural gas processing and industrial CO2 capture processes.

Syngas conversion to liquid fuels

FTS is a core technology for electro-biofuels production. It reacts carbon monoxide with hydrogen to form a mix of hydrocarbons known as synthetic crude, or syncrude. Syncrude, like fossil crude, must be refined to yield marketable liquid fuels.

Hydrocracking, hydrodeoxygenation and hydrotreating may be required to achieve the ‘Jet’ specification for aviation kerosene. These are standard processes which are used on many petroleum refineries today. The emerging world of electro-biofuels can leverage experience and expertise from the established energy sector.

FTS tends to produce a mix of linear, paraffinic hydrocarbons of various chain lengths. Some of these paraffins are too short to be used as diesel or kerosene, and others are too long. The long, waxy molecules can be hydrocracked to make smaller chain hydrocarbons which are suitable for diesel and kerosene. Hydrogen is reacted with the waxes in the presence of a catalyst to crack them.

During FTS, it is likely that some alcohols and esters may be formed. These molecules are referred to as oxygenates. They can be corrosive and damaging to fuel storage infrastructure. So, hydrogen is reacted with them to remove the oxygen atoms and yield water.

Isomerisation to avoid fuel freezing

Another processing requirement of FTS syncrude is isomerisation. A mixture of linear hydrocarbons can freeze at the very cold temperatures encountered during high altitude flight. Isomerisation converts the long straight paraffins to branched hydrocarbon isomers. These can be imagined to look like a tree with branches rather than a long stick. Isomerisation takes place in a reactor in the presence of hydrochloric acid and a catalyst, which is often based on platinum.

Linear hydrocarbons freeze at cold temperatures. This issue is well known in the diesel supply chain where winter diesel is sold during colder months to avoid solid fuel blocking the fuel feed system.

Isomerised, non-linear molecules remain liquid at colder temperatures. This is essential for aviation fuel, since the temperature at high altitude can be as low as -40 °C. The ‘Jet’ fuel specification controls this safety-critical aspect of liquid fuel quality.

The isomerisation reaction itself does not consume hydrogen. However, hydrogen is added in the overall isomerisation process to support side reactions such as cracking of carbon-carbon double bonds that may simultaneously take place.

Bankability and investibility

The energy transition is awash with project ‘announcements’, many of which never proceed beyond a pre-feasibility study. Sadly some of them are pure ‘investor-bait’ or poorly conceived still-born projects.

On the other hand, hybrid electro-biofuels projects are perceived by many to be in the sweet spot of clean fuels, and are being catalysed by the biofuel and PtL sub-mandates within SAF adoption regulations in the EU and UK.

These are the kinds of projects that should, and will, make it through FEED and FID to commercial operations.

As an example, at their BioTJet project in Pardies, France Elyse Energy has proposed biomass torrefaction, grinding and entrained flow gasification using the thyssenkrupp PRENFLO® technology for syngas generation.

Syngas processing and FTS fuels production and upgrading will then take place using the Axens GASEL® technology. Axens is both an equity partner and key technology licensor will provide performance guarantees around many aspects of this project.

32,000 tonnes per year of electrolytic green hydrogen will enrich the hydrogen content of the gasifier syngas to produce SAF and naphtha as bio-electro fuels. The electrolyser park is known as H2-Lacq.

BioTJet and H2-Lacq are two key components of the wider E-CHO industrial hub project, which additionally includes bio/e-methanol production from electrolytic hydrogen and the CO2 produced during the biomass gasification process. This aspect of the project is referred to as eM-Lacq.

The integrated plant is slated to go online towards the end of this decade.

***

Author credit – Stephen B. Harrison, sbh4 consulting.

sbh4 is an independent advisory firm focused on decarbonisation and defossilisation through e-fuels, e-fertilizers, biofuels, SAF, CCTUS, GHG emissions reduction, and the emerging hydrogen economy. For more information, visit www.sbh4.de.