Rectifier technology selection for hydrogen electrolyser schemes

Transformers cascade high voltage electricity from the transmission grid to the lower voltage required by electrolysers. Rectifiers convert the alternating current (AC) that is used in the grid to the direct current (DC). Harmonic filters ensure that the electrolyser park does not disrupt the grid. Power factor correction may also be required.

Power management equipment represents around 20% of the equipment capital cost of a typical electrolytic hydrogen scheme. This cost is generally shared equally between the switch gear, transformers and rectifiers.

Without a robust, stable power supply the electrolysers will not operate. And, there are risks to the grid if the power management equipment at the electrolyser park is inadequately specified. With so much at stake, selection of the most appropriate power management technology is crucial.

Rectifier technologies

Rectifier technology has advanced significantly in recent decades. This has been driven by the increased use of PV solar and battery energy storage systems (BESS), both of which require DC power.

Several rectifier classifications are available on a commercial basis. They offer technology selection options for electrical engineers as they specify power management equipment for electrolyser schemes.

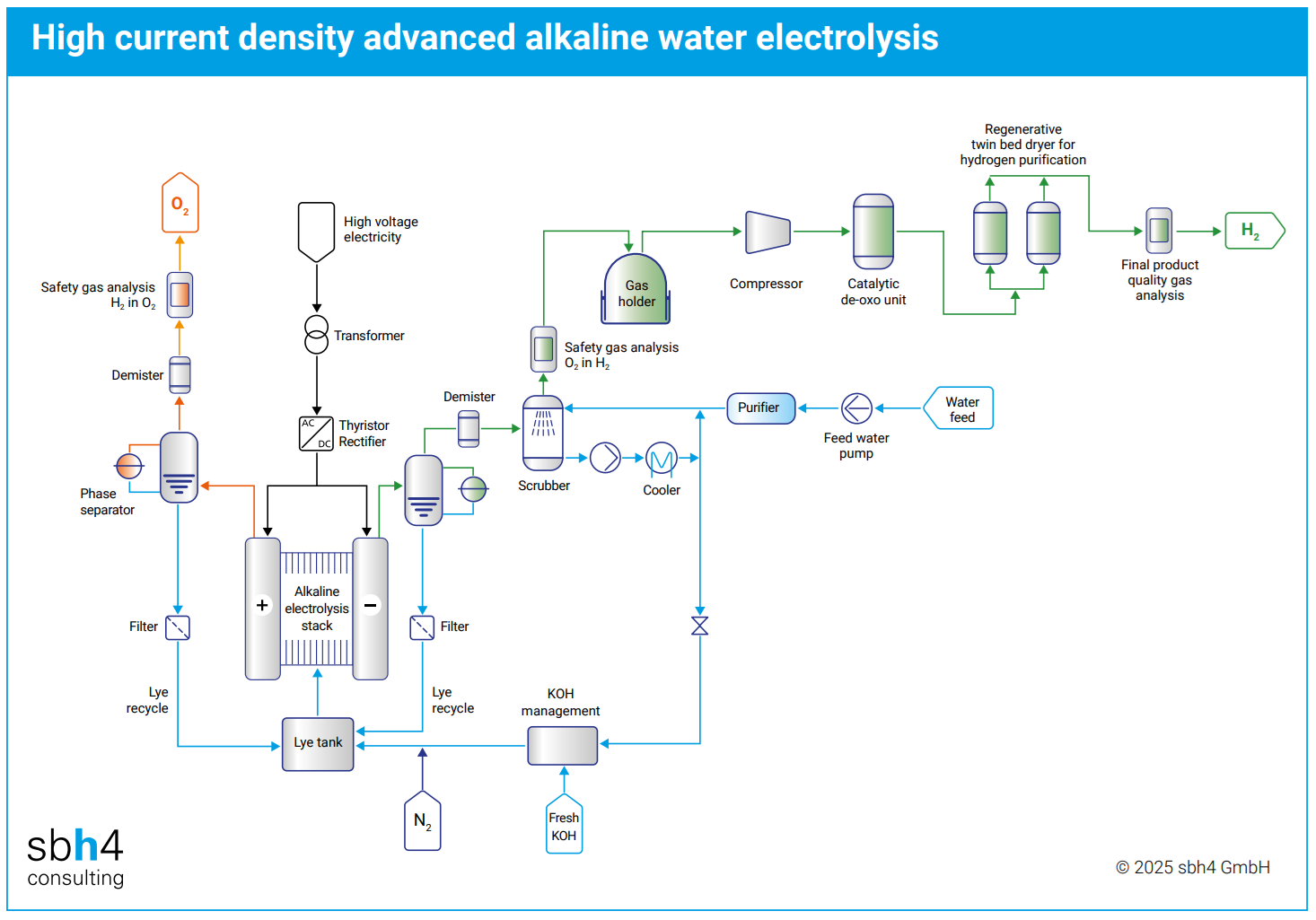

Thyristor rectifiers for advanced alkaline electrolysers

Thyristor-based silicon-controlled rectifiers (SCRs) have been used for decades to power electrolysers used for chlorine and sodium hydroxide production in the chlor-alkali industry. More recently, they have become the default choice for advanced alkaline electrolyser systems for hydrogen production.

High current density advanced alkaline electrolysers, traditionally the domain of thyssenkrupp Nucera, are also being offered by challengers such as INEOS Electrochemical Solutions, Sany and HydoTech. Thyristor rectifiers are the only technology that can provide the combination of high current at low voltage that is required by this classification of electrolysers.

Despite their robustness, thyristor rectifiers have severe limitations regarding grid compliance. They generate low power quality, characterised by a poor power factor and high harmonic content. Grid compliance requires the integration of complicated multi-pulse systems or external filter banks, adding to the capital cost and increasing system size.

Thyristor rectifiers are phase-controlled, semi-controlled devices. They leave a large ripple in the DC current flowing to the electrolyser. This means the electrolyser electrodes oscillate around their point of maximum Faradic efficiency.

Thyristor rectifiers themselves are less expensive than more modern technologies. However, when the cost of the additional power conditioning equipment is considered, the total capex will be similar to more advanced technologies. Furthermore, the lower efficiency of thyristor rectifiers and their ripple currents increase their lifetime cost of ownership versus more efficient technologies.

IGBT – perfect for PEM

Passive diode rectifiers represent the simplest solution for AC/DC conversion. However, they have a potential for severe harmonic distortion of the grid because they do not include internal control circuitry.

To overcome this problem, modern diode rectifiers include an active component to manage the DC output. A common configuration incorporates a buck-type chopper utilising Insulated Gate Bipolar Transistors (IGBT) switches after the diode rectifier.

The combined diode and IGBT rectifier topology achieves high efficiency and low harmonics. This configuration and has resulted in IGBT rectifiers becoming the default choice for modern PV solar parks and lithium-ion BESS.

Diode rectifier - image courtesy of sbh4

Compared to thyristor rectifiers, IGBT reduces the DC ripple supplied to the electrolyser stack and ensures the electrolyser is operating at its optimum efficiency. Overall, IGBT rectifiers generally achieve an efficiency of around 98.5% and can reduce the overall power consumption of an electrolyser park by up to 10%, compared to a thyristor rectifier.

IGBT rectifiers can offer a total harmonic distortion (THD) below 5%. This satisfies stringent grid compliance requirements without the need for external passive filters and capacitor banks which would be required to achieve this low THD when using a thyristor rectifier.

A limitation of the IGBT technology is that it cannot supply the high current density required by advanced alkaline electrolysers. IGBT is therefore better aligned with PEM or traditional alkaline water electrolysers, which operate with a lower current density.

The dynamic performance of IGBT rectifiers is excellent. They align perfectly with variable and intermittent renewable power supply - situations where PEM electrolysers are often specified.

SiC – the next generation

Silicon Carbide (SiC) is a wide bandgap (WBG) semiconductor material which may become the successor to silicon IGBTs. It is a new technology with limited commercial availability at present. Furthermore, it has the highest capex cost .

SiC semiconductors are around four times the price of silicon that is used in IGBT rectifiers. When considering these semiconductors within the overall rectifier system they can add several percentage points to the total capital cost. However, the cost of SiC semiconductors is likely to fall as this technology is adopted and production scales.

SiC offers faster switching speeds, superior thermal properties, and reduced losses versus IGBT. It yields an efficiency improvement of more than 1% compared to IGBT and can achieve a rectification system efficiency to more than 99%.

SiC Silicon Carbide - image courtesy of sbh4

Electricity is a major cost of electrolyser operation. The capital cost of the rectifier is depreciated over the lifetime of operation, generally 20 to 25 years. Investing in a 1% efficiency improvement will cost more on day-1, but over the lifetime of the project, the efficiency gain may save many times this capital cost penalty due to reduced electricity consumption.

The cost of electricity and the financing vary from project to project, so each case must be assessed based on its unique conditions. However, in many electrolytic hydrogen projects, there will be a good business case for using the most advanced SIC rectifiers in the coming decade.

The ability of SiC rectifiers to switch at significantly higher frequencies leads to an increased power density and a smaller footprint. This means they can fit into small containerised electrolyser systems. They can also offer advantages for electrolysers mounted on offshore structures exploiting renewable wind power.

Turquoise hydrogen electricity supply

Electrification of a wide range of industrial processes using nuclear, hydro and renewable power generation is taking place. This will support a reduction in greenhouse gas emissions and thereby help to mitigate climate change. Beyond electrolytic hydrogen production, some turquoise hydrogen production techniques also require DC electricity and the associated rectifiers.

Turquoise hydrogen production can be achieved using microwaves, thermal energy, AC plasma or DC plasma. When DC plasma is the chosen pathway, the process will require rectification of AC from the grid to DC electricity for the plasma generator.

Large DC plasma torches consume more than 10MW of power, so DC plasma turquoise hydrogen projects will be deployed at a similar scale to hydrogen electrolyser schemes.

***

Author credit – Stephen B. Harrison, sbh4 consulting.

sbh4 is an independent advisory firm focused on decarbonisation and defossilisation through e-fuels, e-fertilizers, biofuels, SAF, CCTUS, GHG emissions reduction, and the emerging hydrogen economy. For more information, visit www.sbh4.de.