Trina Green Hydrogen launches integrated hydrogen refuelling station solution

Trina Green Hydrogen has jointly launched an integrated solution for hydrogen production and refuelling stations with the Spanish company Clantech.

This collaboration combines Trina Green Hydrogen's advanced electrolysis water hydrogen production technology with Clantech's expertise in engineering design and system integration, targeting the core pain points of the development of the green hydrogen industry in Europe.

At present, the development of the hydrogen energy industry in Europe is in a critical period of transition from "policy driven" to "market driven".

The EU and governments around the world are vigorously promoting network construction and green hydrogen production through mandatory regulations and funding subsidies.

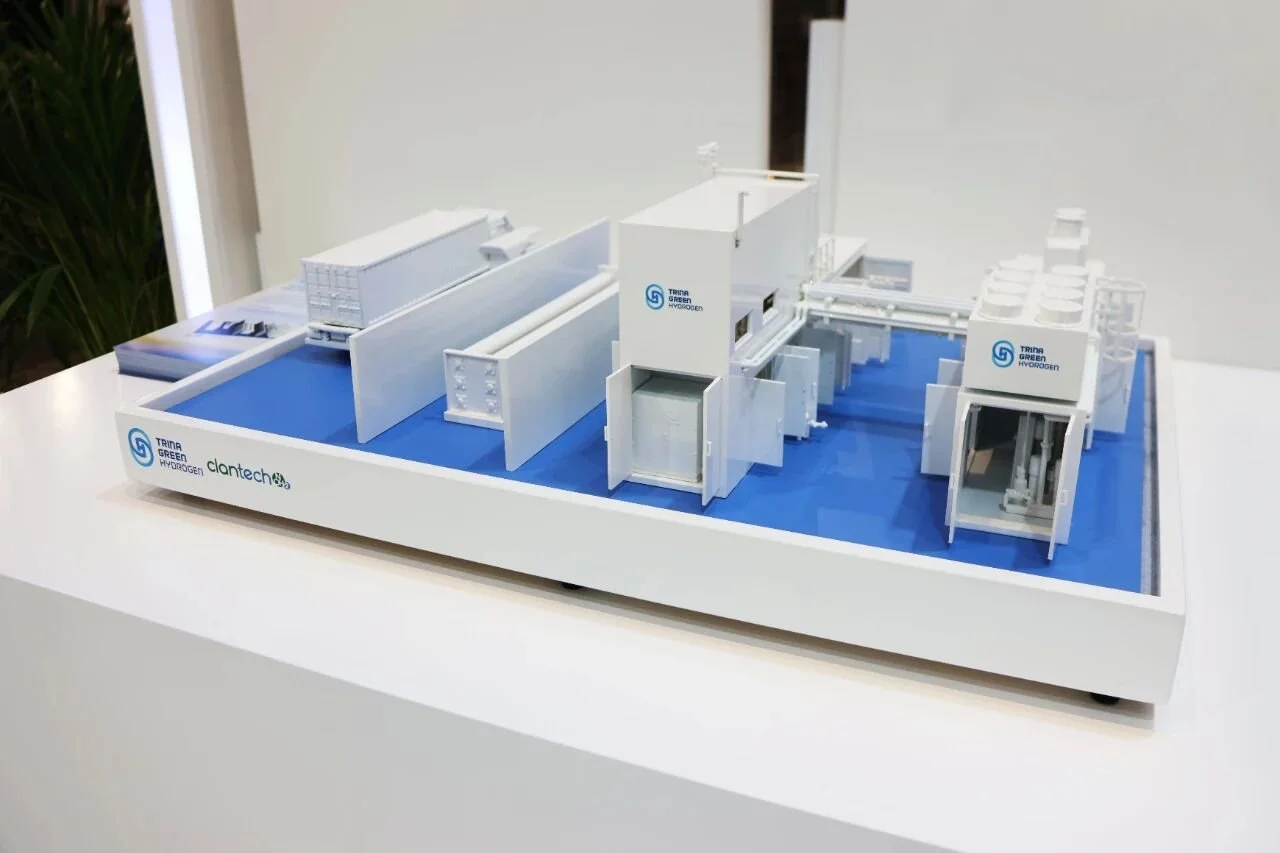

Image ©Trina Green Hydrogen

Meanwhile the industry continuously reduces costs and increases efficiency through technological innovation, and clearly regards long-distance heavy logistics as the core breakthrough point. Compared with pure electric solutions, hydrogen powered trucks have significant advantages in range and refuelling time, making them very suitable for long-distance logistics. The EU's Alternative Fuel Infrastructure Regulation mandates the construction of one hydrogen refuelling station every 200 km on the EU's core transportation network by 2030.

Based on consideration of the demand in the European market, Trina Green Hydrogen and Clantech have jointly released an integrated solution for hydrogen refuelling stations. The plan uses a standard unit of 100 standard cubic meters to integrate key equipment such as alkaline hydrogen production equipment, gas-liquid separators, purification and drying devices, and liquid driven compressors into a standard container. The hydrogen can be compressed to 50MPa for storage and supplied for single heavy-duty trucks or buses to refuel. The PLC control room can coordinate the control of hydrogen production and refuelling stations, achieve the overall management of hydrogen production and refuelling, and ensure the safety of the entire station through HAZOP/SIL analysis.

Standard container design not only facilitates fast and convenient transportation but also makes on-site construction more efficient. The pipelines between containers are arranged overhead, greatly reducing the workload of on-site civil engineering. Modular design allows for rapid replication based on hydrogen demand to meet market demands. At present, the plan has been implemented and applied in the transportation demonstration project of the Portuguese government and has obtained BV certification.

The integrated solution for hydrogen refuelling stations released by Trina Green Hydrogen closely combines its efficient and reliable core products with Clantech's localised design concept, providing the industry with a convenient, fast, and cost-effective overall solution.

Trina Green Hydrogen has focused on the European market and has established a subsidiary in Spain, actively cooperating with local European enterprises and institutions. This collaborative model not only provides technologically advanced hydrogen equipment but also creates a comprehensive service system that meets the needs of the European market.

For more information, visit www.trinahydrogen.com.