Enapter AG launches Nexus 2.5 MW multicore electrolyser

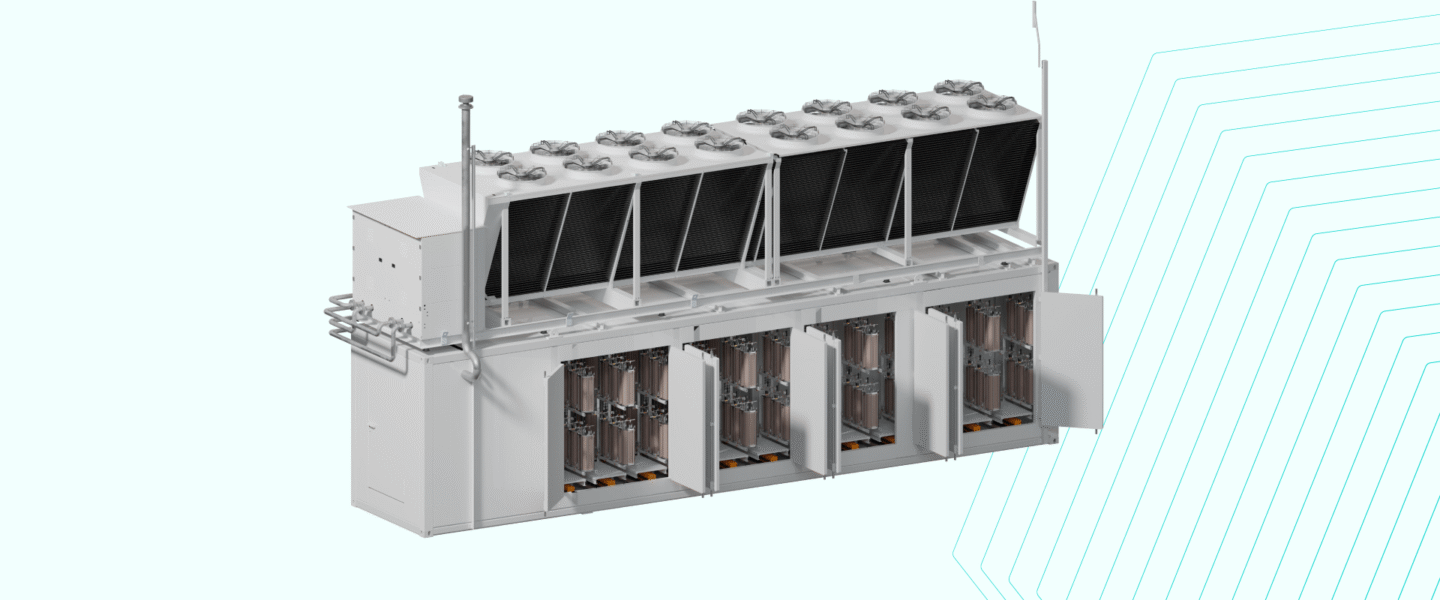

The market leader in anion exchange membrane (AEM) electrolysers Enapter AG is expanding its product portfolio with a 2.5 MW multicore electrolyser.

Thanks to the use of new, more powerful stacks, it offers significantly more power than the current 1 MW multicore electrolysers while maintaining the same 40-foot container.

The Nexus 2500 is fully compatible with all Enapter multicore electrolysers, and end-users can combine all products from the now expanded Enapter product portfolio to expand their systems.

The Nexus 2500 can produce over one ton of green hydrogen with a purity of 99.999 percent within 24 hours. Image ©Enapter

In addition to the proven design, the Nexus 2500 is also available as a skid-mounted version for indoor installation. Indoor installations are more efficient than individual containers, especially for multi-megawatt projects.

With the new Nexus 2500 multicore electrolyser, Enapter is opening up new markets and customer groups for large-scale hydrogen production plants on an industrial scale.

The electrolyser can be used, for example, in steel and ammonia production and in refuelling stations for heavy-duty vehicles. Another area of application is the storage of surplus energy from solar and wind farms in the multi-megawatt range.

The Nexus 2500 can produce over one ton of green hydrogen with a purity of 99.999 percent within 24 hours.

Enapter’s unique modular design is also used. Each of the approximately 100 stacks installed can be ramped up or down independently to make optimum use of the power from renewable energy sources. This makes Enapter multicore electrolysers particularly interesting for hydrogen production from fluctuating energy sources such as solar and wind, where power generation can vary greatly over the course of the day due to climatic influences.

Like all Enapter multicore electrolysers, the Nexus 2500 is controlled by Enapter's latest AI software. The proprietary artificial intelligence analyses data from the measuring sensors installed in the electrolyser, which record temperature, pressure and power consumption at various points. The artificial intelligence controls the device in real-time and can intervene where necessary, enabling improved energy flow and further increasing the efficiency of the device.

Dr Jürgen Laakmann, CEO of Enapter, said: “After more than 18 months of development, we are now adding another multicore electrolyser to our product portfolio. The Nexus 2500 delivers 2.5 times the power of the Nexus 1000 electrolyser while being the same size. This is made possible by the use of new, more powerful stacks. In large-scale projects in the multi-megawatt range, space is just as important as efficiency. And with the Nexus 2500 as a container or skid-mounted version, we are now in a position to offer our highly efficient electrolyser technology in our proven modular design for these projects as well.”

The Nexus 2500 is now available for pre-order. First deliveries are planned for the end of 2026.

For more information, visit www.enapter.com.